Chadwick Technology has undertaken subcontracts involving design, supply and installation of cladding systems on many major projects including:

- Abu Dhabi International Airport - Midfield Terminal Building

- Dubai Metro - Red Line + Green Line

- Dubai International Airport - Terminal 3

- Adelaide Convention Centre

- Second Bangkok International Airport

- Putrajaya Convention Centre, Malaysia

- Dover Station, Singapore

- Expo Station, Singapore

- Singapore Turf Club

- KLCC Concert Hall, Malaysia

- Hong Kong Airport – NW Concourse + East Hall Extension

- Kuala Lumpur International Airport

- Sydney Aquatic Centre

- Singapore Indoor Stadium

- Sydney Football Stadium

- Sydney Exhibition Centre

- Sydney Convention Centre

- National Maritime Museum, Sydney

- Sydney Aquarium

- Sydney Entertainment Centre

- National Tennis Stadium, Melbourne

- Tomago Aluminium Smelter, NSW, Australia

Engineering Design

Chadwick Technology has been awarded Excellence in Engineering Awards by the Institution of Engineers Australia and Gold Circle Awards for Roofing Innovation from the National Roofing Contractors Association - USA. The design checklist for Chadwick Composite Systems is extensive and includes considerations of items such as:

- Structural requirements

- Deflection limitations

- Dead load considerations

- Wind load considerations

- Thermal requirements

- Condensation considerations

- Hydraulic requirements

- Fire resistance

- Material compatibility

- Sound absorption

- Sound transmission loss

- Installation efficiency

- Buildability

- Health and safety considerations

- Material procurement

Manufacturing

Much of the subcontract work we do involves on site manufacturing. Particularly for large projects, projects in remote areas, or where transportation of large fabricated components is not an option. On site manufacturing includes roll forming of structural decks and roof sheets, fabrication and painting of secondary steelwork, and glazed skylight prefabrication. These techniques have been successfully employed on the following projects:

- Abu Dhabi International Airport

- Roll forming roof sheets

- Dubai Metro

- Roll forming roof sheets

- Roll forming structural decks

- Prefabricate skylights

- Dubai International Airport

- Roll forming roof sheets

- Roll forming structural decks

- Prefabricate skylights

- Second Bangkok International Airport

- Fabricate and paint secondary steelwork

- Roll forming roof sheets

- Prefabricate skylights

- Prefabricate louvres

- Singapore Expo Station

- Roll forming roof sheets

- Roll forming structural decks

- Prefabricate skylights

- Kuala Lumpur International Airport

- Roll forming roof sheets

- Roll form ceiling strips

- Sydney Aquatic Centre

- Prefabricate skylights

Quality Assurance

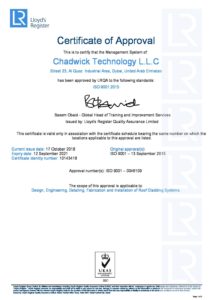

Chadwick Technology’s Quality Management System is certified to ISO 9001:2015 standard. Our Certificate of Approval is issued by Lloyd’s Register Quality Assurance Limited (LRQA).

Our Quality Management System is at the core of what we do and covers all stages of project delivery including design and engineering, material procurement and testing, fabrication and installation of cladding systems.

The certification from LRQA includes six monthly audits to ensure on going compliance. We are also regularly audited by our clients and their consultants.

Product Testing

As part of the development process, all Chadwick Technology’s new products are extensively tested prior to manufacture and application. Testing facilities used by Chadwick Technology include:

Testing can be for a variety of performance requirements which may include:

- Structural Efficiency

- Watertightness

- Pressure Resistance

- Acoustic Performance (sound absorption and sound transmission loss)

- Impact Resistance (e.g. hail etc)

All testing is undertaken under the supervision of Chadwick Engineering Staff, together with our Engineering and/or Acoustic Consultants.

Consultation

In addition to our core subcontracting work Chadwick Technology can provide roof and cladding consultancy services. Projects that have been undertaken as a consultant include:

- Incheon International Airport, Seoul, South Korea

- Football World Cup Stadiums, South Korea

- Khalsa Heritage Centre, Punjab, India

- Australian Pavilion, Venice Biennale, Italy

Consultancy scope may include:

- Systems design

- Roofing product development

- Roof engineering (structural – hydraulic)

- Product review & testing

- Estimating and costing

- Construction review/supervision

- Reporting on existing roofing conditions